GENENCOR INTERNATIONAL BV (PART OF DUPONT INDUSTRIAL BIOSCIENCES GROUP)

During the project DuPont has developed an improved fermentation process for enzyme production at lab-scale. The old fermentation protocol has been analyzed and different parameters have been adjusted based on the outcome of a mathematical model that was developed during the project. Next to that, work has been done to improve the production strain such that a better quality of enzyme is produced by the

During the project DuPont has developed an improved fermentation process for enzyme production at lab-scale. The old fermentation protocol has been analyzed and different parameters have been adjusted based on the outcome of a mathematical model that was developed during the project. Next to that, work has been done to improve the production strain such that a better quality of enzyme is produced by the

strain. During the project, it was decided to change the formulation of the enzyme from a dried product to a liquid product. Lab scale work has been done by DuPont to change this formulation with success. Both the new fermentation protocol as well as the new formulation have been transferred to partner BBEPP for scale-up to pilot level and later to industrial scale.

BIO BASE EUROPE PILOT PLANT VZW

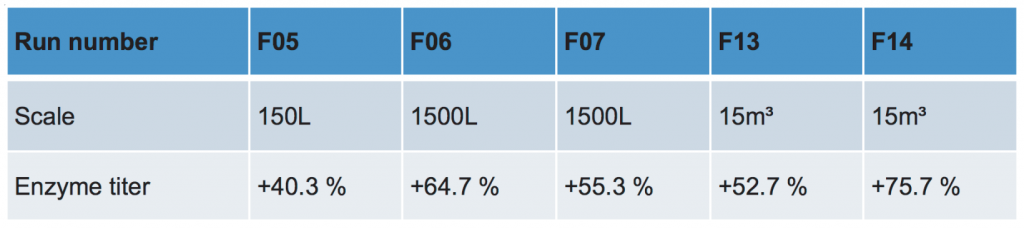

During the DEMETER project, the enzyme production process was optimized in order to increase the enzyme titer by at least 50%. Bio Base Europe validated the improved fermentation process first at small pilot scale, and in a second phase up-scaling was done to a 1500L and 15m³ scale.

During the DEMETER project, the enzyme production process was optimized in order to increase the enzyme titer by at least 50%. Bio Base Europe validated the improved fermentation process first at small pilot scale, and in a second phase up-scaling was done to a 1500L and 15m³ scale.

The table below shows the improvement (compared to the original process) of the enzyme titer after fermentations at different scales.

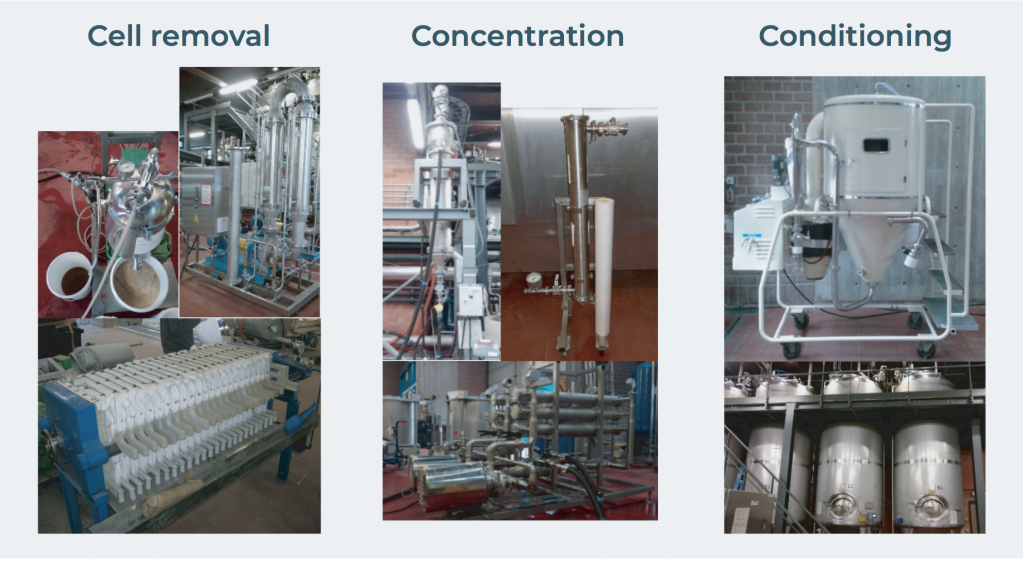

To recover the enzyme from the fermentation broth, different downstream processing (DSP) steps were tested at different scales. The DSP approach consist of a cell removal step, a concentration step and a conditioning step. Examples of equipment that was tested and compared is shown in the figures below. The best equipment was selected based on the highest recoveries, industrial availability and shortest process time.

MIAVIT GMBH

In the past few months, the data from the large-scale plant trials carried out have been collected and evaluated. MIAVIT has carried out enzyme tests at 4 locations to increase the efficiency of agricultural biogas plants.

In the past few months, the data from the large-scale plant trials carried out have been collected and evaluated. MIAVIT has carried out enzyme tests at 4 locations to increase the efficiency of agricultural biogas plants.

It became clear with all systems that it is difficult to include such tests in daily operations. Fluctuations in substrate inputs as well as technical problems during the trial period occurred. To summarize the results, it can be concluded that in some cases a possible increased efficiency of substrate degradation was observed. Changes in the rheological properties in the form of reduced power consumption of the agitators were also detected. Thus, positive effects of the enzyme addition on the fermentation process were found in some AD plants and it can be said that an improvement of the biogas process with economic applicable dosages is possible.

DBFZ – DEUTSCHES BIOMASSEFORSCHUNGSZENTRUM GEMEINNUETZIGE GMBH

In the past weeks, investigations and evaluations at DBFZ were completed. The work focused on finalising also the evaluation, from laboratory tests as well as the full-scale trials within work package 4.2. The last deliverables are about to be finalised, dealing with the development of a tool for plant evaluation, a guideline for plant operation and the evaluation of the full-scale trials.

In the past weeks, investigations and evaluations at DBFZ were completed. The work focused on finalising also the evaluation, from laboratory tests as well as the full-scale trials within work package 4.2. The last deliverables are about to be finalised, dealing with the development of a tool for plant evaluation, a guideline for plant operation and the evaluation of the full-scale trials.

Within the investigations at DBFZ, a peer-reviewed paper was also published. It focuses on the comparison of different methods for describing effects of substrate disintegration on the methane yield. The performed statistical evaluation underlines the importance of careful design and precise conduction of experiments, how it was considered in the laboratory tests within DEMETER. The article which represents the result of a combined work conducted jointly with OWS is published (open access) in Chemical Engineering & Technology 2020, 43, No. 1, 47–58 with the title “Assessing the Effects of Substrate Disintegration on Methane Yield” (available at the following link: https://onlinelibrary.wiley.com/doi/full/10.1002/ceat.201900393?af=R

ORGANIC WASTE SYSTEMS NV

During the final stages of the DEMETER-project, OWS conducted full scale trials in two DRANCO-plants. DRANCO is an anaerobic digestion technology that allows working with high TS-content in the digester (> 25% TS) and is most often used to treat solid waste streams. Both plants in the trial used source separated organic household waste as their primary input substrate. The trials consisted of a reference period, a test period during which the C1-enzyme was dosed and finally a phase out period. During the trial an array of process parameters were monitored and several samples of input and digestate were analysed. Running trials on waste treatment plants came – as expected – with its challenges: the input is very variable both in quality and quantity. Therefore, an additional reference period was selected (the same period the year before), during this additional period, only some of the parameters monitored were available as it was initially out of scope.

During the final stages of the DEMETER-project, OWS conducted full scale trials in two DRANCO-plants. DRANCO is an anaerobic digestion technology that allows working with high TS-content in the digester (> 25% TS) and is most often used to treat solid waste streams. Both plants in the trial used source separated organic household waste as their primary input substrate. The trials consisted of a reference period, a test period during which the C1-enzyme was dosed and finally a phase out period. During the trial an array of process parameters were monitored and several samples of input and digestate were analysed. Running trials on waste treatment plants came – as expected – with its challenges: the input is very variable both in quality and quantity. Therefore, an additional reference period was selected (the same period the year before), during this additional period, only some of the parameters monitored were available as it was initially out of scope.

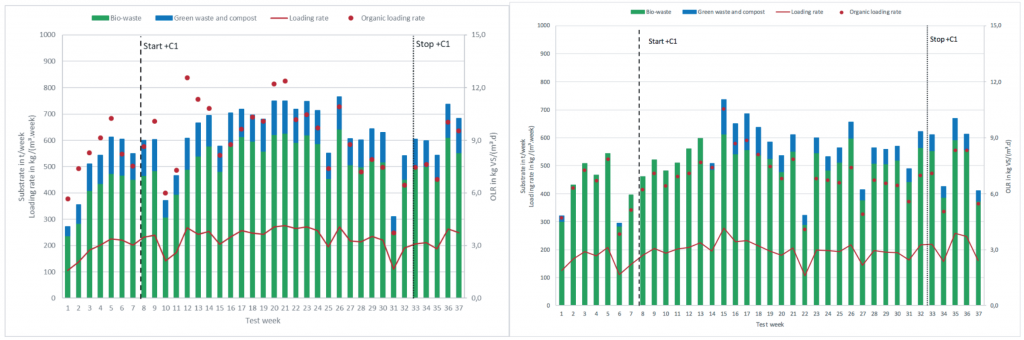

Figure 1 LEFT: Substrate mix and loading rate during trial period; RIGHT: Substrate mix and loading rate in the year before trial period (additional reference period). Start and stop of C1 addition indicated (please note that no C1 was added during the additional reference period).

In the above figure, the substrate mixture and loading rate during the trial period and the additional reference period is shown. The figure clearly shows the fluctuations in input quantity and quality and the fluctuations in loading rate. By selecting a short period in which steady state was assumed, DBFZ calculated an increase in degradation efficiency of 17% with the use of C1. While this is a result that was hoped for, it needs to be carefully interpreted: steady state was only assumed and the quality of the input mixture was most certainly different in the selected period. Both factors have tremendous impact on the degradation efficiency as well.

CIAOTECH Srl

In the last months of the DEMETER project, CiaoTech has completed the activities in the frame of the WP5. In particular, the Business Plan has been developed and the Techno-Economic Assessment (TEA) and Life

In the last months of the DEMETER project, CiaoTech has completed the activities in the frame of the WP5. In particular, the Business Plan has been developed and the Techno-Economic Assessment (TEA) and Life

Cycle Assessment (LCA) have been also performed.

The Business Plan is mainly based on market and technology trends previously identified and on the study of the competitive solutions already available on the market. Moreover, the commercialisation strategy for the DEMETER C1-enzyme is also described according to the business model that the partners will use after the project end.

Concerning the TEA, the analysis, based on the results achieved within the biogas field trials, has demonstrated that the biogas production system is more profitable when using the c1-enzyme compared to the traditional system (that does not use any enzyme).

Finally, an attributional LCA was performed, including all steps in the production of biogas from waste feed materials collection and enzymes production to biogas storage. The performed study has demonstrated a positive environmental impact of the DEMETER project compared to the traditional biogas production process.