DEMETER latest technical updates on small scale lab test for performance of enzymes in biogas applications

Significant progresses have been made by the DEMETER partners in terms of technical improvements. Focusing on the enzyme production, the fermentation process was successfully implemented by BBEPP on all scales (at 150L, 1500L and 15m³ scale); moreover, the purification and stabilization process was improved and the targets for Downstream Processing were achieved.

The effect of enzyme addition to the anaerobic digestion was investigated at DBFZ in two digesters (189 m³) using sorghum silage and cattle manure as substrate. In addition to the biogas production, further parameters were measured, and a positive enzyme effect on the viscosity of the digestate was observed.

OWS evaluated the enzyme effect on the biogas production as well. In particular, two types of lab-tests were performed. Within the batch test, the production of volatile fatty acids (VFA) was measured. And, a wide variety of substrates were tested: from agricultural substrates (e.g. corn silage, corn stover, manure) over household waste (different types of vegetable garden and fruit (VGF) waste and the organic fraction of municipal solid waste (OF-MSW)) to waste water treatment plant (WWTP) sludge. The enzyme had a positive effect on the production of VFA, and more in general, the enzyme was found to be active in an anaerobic environment at both thermophilic and mesophilic temperature. By performing the semi-continuous test, the long-term effects of the enzyme on different aspects of the digestion process were evaluated. The data showed that there were no adverse effects and that the enzyme may attribute to higher biogas yield and a more stable process.

In order to exploit the project results, PNO developed its own innovation intelligence methodology that will allow to identify the market and technology trends and the most important stakeholders involved in the innovations. This method was based on the analysis of external technologies, innovators, end users and suppliers, by using a combined database of 50 thousand research projects, European, US, WIPO, Japanese and Chinese patents – overall more than 60 million – all translated in English, as well as 10 million papers and scientific articles published in Open Access.

BIO BASE EUROPE PILOT PLANT VZW

The enzymes were produced at BBEPP at 150L, 1500L and 15m³ scale. The improved fermentation process was successfully implemented on all scales, yielding the desired enzyme titer at the end of the process. The purification and stabilization process was improved and the targets for DSP were achieved. Enzyme material was provided by BBEPP to the partners to perform the application tests.

The enzymes were produced at BBEPP at 150L, 1500L and 15m³ scale. The improved fermentation process was successfully implemented on all scales, yielding the desired enzyme titer at the end of the process. The purification and stabilization process was improved and the targets for DSP were achieved. Enzyme material was provided by BBEPP to the partners to perform the application tests.

MIAVIT GMBH

Lorena Knobel from MIAVIT stated “When presenting the project content to end-customers of enzymes, we got very contrary opinions. Ones were very skeptical about previous experiences with enzyme or earlier published negative results about enzymes in AD processes. Others were very interested in upcoming results. Positive feedback is based, for example, on experiences that good digestible but expensive substrates can be substituted by hard-to-degrade but cheaper material like straw or manure.

Lorena Knobel from MIAVIT stated “When presenting the project content to end-customers of enzymes, we got very contrary opinions. Ones were very skeptical about previous experiences with enzyme or earlier published negative results about enzymes in AD processes. Others were very interested in upcoming results. Positive feedback is based, for example, on experiences that good digestible but expensive substrates can be substituted by hard-to-degrade but cheaper material like straw or manure.

There is also the opinion that the enzyme product “FibreZyme” must have a very good effect in the biogas sector, as it is a research component of such a large EU project.

Some negative comments are based on previously bad experiences with enzymes. In the beginning of enzyme addition in anaerobic digestion (ca. 10 years ago) wrong enzymes (from other industrial sectors) were used with different pH and temperature optimum. They weren’t optimal for biogas production and thus no or only small effects on biogas process were observed. Enzymes first had to be developed for the biogas process. Furthermore it is in general very difficult to measure effects of enzyme addition in the process. Some customers see good results, others not. Additional biogas yield, produced through enzyme addition is difficult to measure because of the daily fluctuations in biogas production. Generally, it is important to justify the benefits of such a product over the high cost of use.”

DBFZ – DEUTSCHES BIOMASSEFORSCHUNGSZENTRUM GEMEINNUETZIGE GMBH

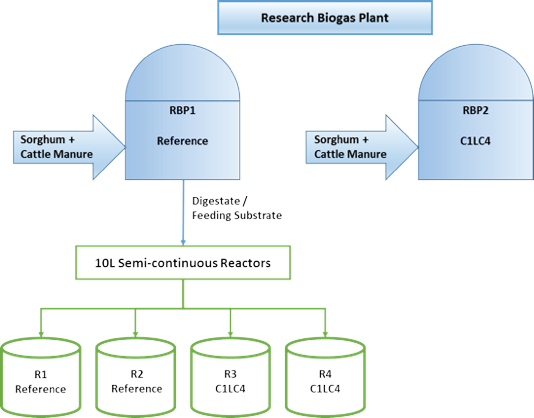

At the research biogas plant of DBFZ the effect of enzyme addition was investigated under practical conditions. In two 189 m³ digesters comparable tests took place. Both digester were operated under same conditions, using sorghum silage and cattle manure as substrate. One digester was used as reference. Test period was divided in three hydraulic retention times (HRT) without enzyme addition and three HRT with addition of C1 in one of two digester. Additional to the biogas production further parameter were measured. Using a pipeviscometer allowed conclusions of an enzyme effect on the viscosity of the digestate.

At the research biogas plant of DBFZ the effect of enzyme addition was investigated under practical conditions. In two 189 m³ digesters comparable tests took place. Both digester were operated under same conditions, using sorghum silage and cattle manure as substrate. One digester was used as reference. Test period was divided in three hydraulic retention times (HRT) without enzyme addition and three HRT with addition of C1 in one of two digester. Additional to the biogas production further parameter were measured. Using a pipeviscometer allowed conclusions of an enzyme effect on the viscosity of the digestate.

In the frame of a bachelor thesis, the effect of C1 on a post-digestion was investigated. The effect was tested on a laboratory scale using four identical 10-liter semi-continuous reactors. Digestate was provided as feeding substrate from the research biogas plant (RBG) within DBFZ.

© N.Kunze 2018, DBFZ

ORGANIC WASTE SYSTEMS NV

OWS concentrated on two types of lab-tests. The first was a batch test in which the potential effect of the enzyme was quantified by measuring the increase in the production of volatile fatty acids (VFA). The second type of test was a (semi-) continuous fermentation test on different substrates, where the long-term effects of the enzyme on different aspects of the digestion process are researched.

OWS concentrated on two types of lab-tests. The first was a batch test in which the potential effect of the enzyme was quantified by measuring the increase in the production of volatile fatty acids (VFA). The second type of test was a (semi-) continuous fermentation test on different substrates, where the long-term effects of the enzyme on different aspects of the digestion process are researched.

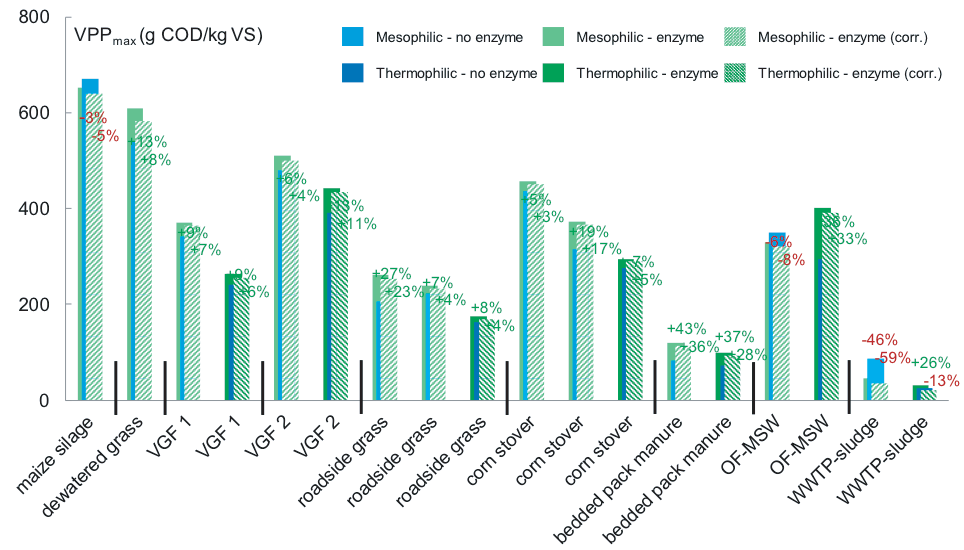

For the first tests, researching the effect of the enzyme on the VFA-production (C2-C6), a substrate was diluted to 8% dry matter. Control reactors only received the diluted substrate, to the test reactors enzyme was added at the start of the test. The reactors were left to anaerobically digest spontaneously at mesophilic (37°C) or thermophilic (52°C) temperature. At regular times, pH was adjusted to 6.5-7. A wide variety of substrates was tested.

Figure 1 shows the results of the tests: the maximum value of VFA (expressed as g COD/kg VS) is shown without enzyme, with enzyme and with enzyme but corrected for the additional COD of the enzyme. From the figure can be concluded that, in most cases, the enzyme has a positive effect on the production of VFA. This proves that the enzyme is active in an anaerobic environment at both thermophilic and mesophilic temperature.

Figure 1. Overview of the effect on VFA production of the enzyme developed in this project in different substrates

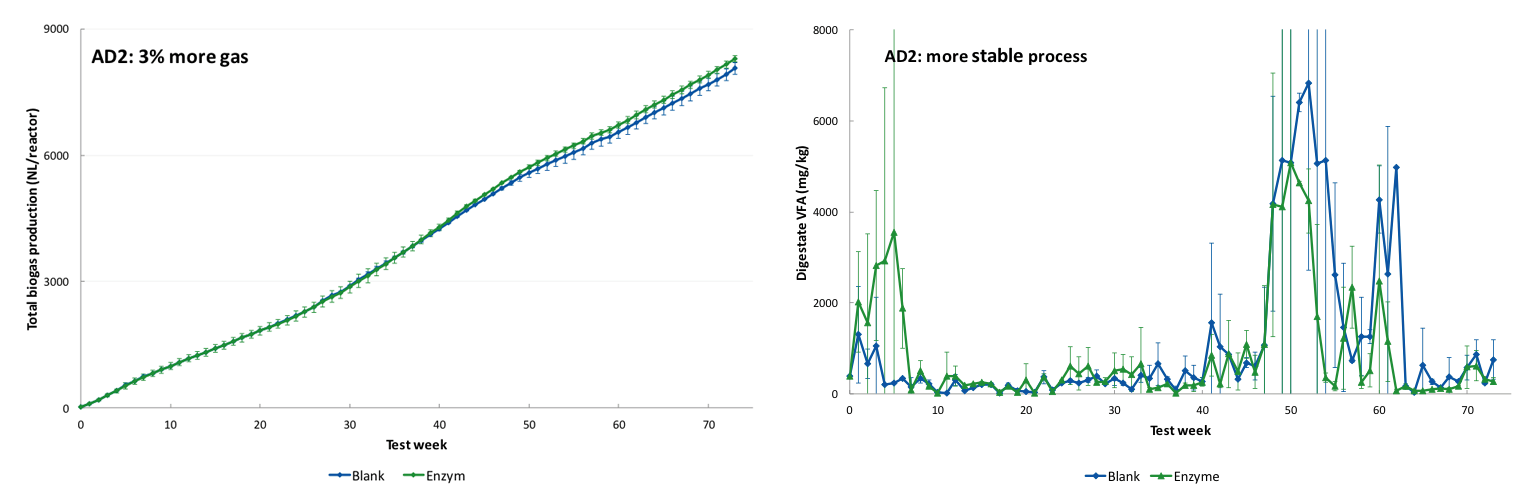

During the second test phase, 4 series of (semi-)continuous digesters were set up. Each series consisted of control reactors (without enzyme) and test reactors (receiving 2 g of enzyme per kg of dry matter of the input mixture). Within one test series, all reactors received the same input mixture and amount. A variety of input mixtures was tested.

In two test series, additional biogas was measured for the reactors receiving enzyme (3% and 4% respectively). Also, the stability of the process increased for some test series with the addition of the enzyme, as can be observed from the fluctuations of VFA in the digestate (Figure 2). Also, the structure of the digestate was researched at regular times, though no conclusive results could be obtained.

Based on the above results, it can be concluded that the enzyme is active in an anaerobic environment at both mesophilic and thermophilic temperature. In lab-scale digestion tests, the effects seen are too small to make hard conclusions. Data does show that there are no adverse effects. Data also suggest that the enzyme developed in this project may attribute to higher biogas yield and a more stable process.

Figure 2.Evolution of the cumulative biogas production (left) and evolution of the VFA-content in the digestate(right) for test series AD2

CIAOTECH Srl

A preliminary analysis, performed by PNO within the DEMETER project, showed that from 2008 to 2018 the EC has funded 86 projects on the biogas topic. The analysis also revealed a sensible increase of the number from the 2010 to 2015. In addition, the research revealed that the majority of the partners of these projects come from Germany, followed by a significant participation in Spain, Italy and UK.

A preliminary analysis, performed by PNO within the DEMETER project, showed that from 2008 to 2018 the EC has funded 86 projects on the biogas topic. The analysis also revealed a sensible increase of the number from the 2010 to 2015. In addition, the research revealed that the majority of the partners of these projects come from Germany, followed by a significant participation in Spain, Italy and UK.

Further a preliminary analysis of patents demonstrated that among the 698 analysed patents, 16 patents belong to Agraferm technologies AG, 14 to DGE Dr.-Ing. Günther Engineering GmbH and 11 to Uts Biogastechnik Gmbh. This data suggests that those actors are deeply involved in the field of biogas technology innovation.

The results obtained thanks to the intelligence analysis are being used in the frame of the projects to:

- develop dissemination, communication and exploitation activities within EU projects

- find potential partners for business collaborations and/or funding proposal

- identify potentially interesting innovations to integrate in their products or innovation plans (open innovation)

- spot innovation trends, incumbent or dis-investing players and competitors

- to elaborate market analysis (on the basis of surveys or direct interviews to the main identified stakeholders) and exploitation strategies